Associate Particle Board

Associate Décor Limited (ADL) operates in the wood panel products space catering to both Indian and International markets. Associate Décor manufactures premium decorative laminates and the most advanced plain & pre-laminated particleboards (Melamine Faced Chipboard) in India.

Associate Particle Board

Particleboards or ‘Chipboards’ are panel products that are engineered from wood. The boards are made using specific sized wood-chips and are bounded by synthetic resin pressed under heat and pressure. The boards produced are denser and more uniform in their constitution as compared to plywood or general wood.

MFC stands for Melamine Faced Chipboards, also known as Pre-laminated Particleboards. An MFC is made using particleboards or chipboards, which are covered on the surface with melamine, impregnated decorative papers, pressed under heat and pressure. This gives the board an attractive and decorative look & feel. MFC’s have a denser and more uniform constitution as compared to general wood and plywood.

Thickness available: 8mm, 18mm, 25mm.

Sizes available: 8ft x 4ft, 8ft x 6ft.

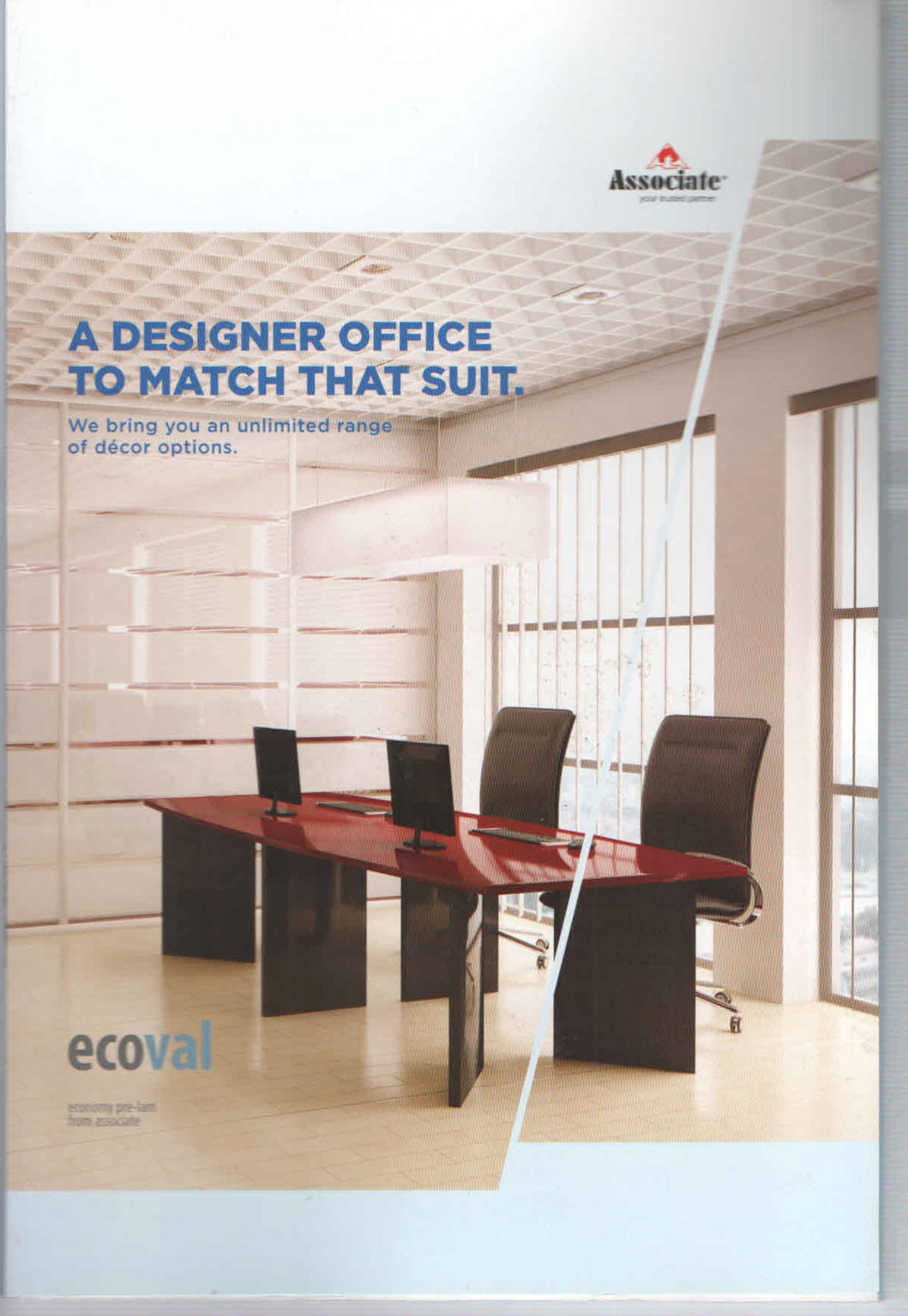

Application

Plain particleboards are used for a variety of applications like interior fixtures, furniture, partitions, false-ceiling, doors, construction related use and industrial applications like circuit boards, speaker boxes, enclosure material, etc. Particleboards are most often used for lamination with materials like melamine films, lacquer films, finished foils, decorative laminates, paint, wood veneers, PVC / PET films, acrylic films / sheets, etc. in order to give them a better look & feel.

WHY ASSOCIATE MFCs

- Associate MFCs are available in the widest range of decors and surface textures, which are trendy and attractive. More than 1000 decors make up the MFC collection. These MFC’s are made using the world’s most advanced engineered chipboards as a substrate. Besides this, Associate MFC’s also show the following qualities:

- Over 1,000 decors, 100% European designs & surface textures

- Three layered boards, made on the I-Beam principle, giving it solid strength and flexibility

- High density core material and high load bearing capacity

- Latex free, with virtually no foreign particles (thereby offering longer tool life) and can be processed cleanly without chipping

- High internal bond strength

- 100% defect-free surfaces and edges

- World-class quality resin production in-house, for flawless lamination and surface leveling

- High abrasion surface lamination

Notes

* The samples shown here are only indicative of the colour / décor patterns and textures available.

* Special textures other than ST02 Matt will be available only against order with a minimum quantity of 1000 boards.

* Shades, Sizes and Thickness which are not readily available will require a minimum time of 15 to 20 days from the date of placing the order.